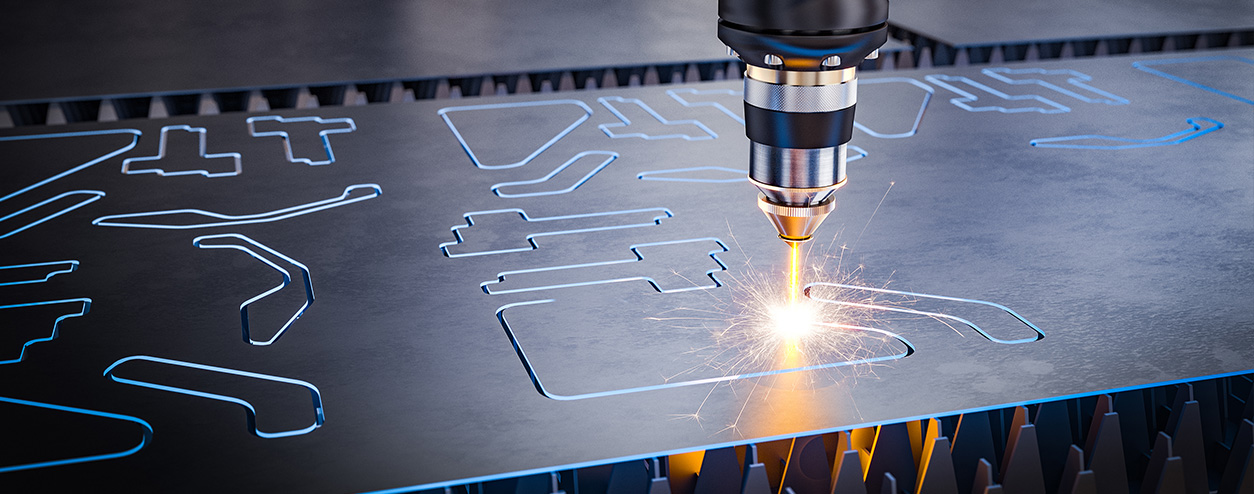

Plate cutting

Laser technology has successfully superseded classic machining technologies in many cases. This technology is determined for cutting and possibly for marking shapes of any complexity into flat workpieces from structural and premium steel and carbon alloys, into the thickness as mentioned below. This technology guarantees the cutting area free of any rags and oxidation, free of surface scratching.

In addition, JET/CAM programming guarantees the maximum utilization of the metal sheet area and high manufacturing accuracy with the maximum utilization of the workpiece area.

2D panel cutting of plate

1 x TRULASER 3030 (L20) cutting center with Loadmaster

Equipped with CoolLine technology (by means of water cooling, it cuts materials 15 – 20 mm thick).

It results in bigger plate utilization with only 4 mm bridges between individual firings.

Maximum plate dimension of 3000 x 1500 mm

Maximum cutting thickness

- Steel - 20,0 mm

- Stainless steel - 12,0 mm

- AL alloys - 6,0 mm

2 x TRUMPF L3030 cutting centres

Maximum plate size of 3000 x 1500 mm

Maximum cutting thickness

- Steel - 20,0 mm

- Stainless steel - 12,0 mm

- AL alloys - 6,0 mm

1 x TRUMPF 4001 cutting centre

Max. plate size of 3000 x 1500 mm

Maximum cutting thickness

- Steel - 20,0 mm

- Stainless steel - 10,0 mm

- AL alloys - 6,0 mm

Grinding machines for reversible needling and edge rounding utilizing new technologies to increase production efficiency.

Lissmac SBM – L G1S2

Lissmac SBM – M B2

Maximum part width: 1500 mm; maximal part thickness: 20 mm

Plate cutting by burning: by means of gas and/or plasma

1. Oxygen-burning: oxygen + acetylene

Burn machine type: SH 5000 - 14 burners, manufactured by MESSER Griesheim

Burn machine type: CORTINA 4000 M - manufactured by MGM Tábor

2. Plasma burning

Burn machine type:

- Omnicut 4000 M – Plasma source of HPR 260, manufactured by MGM Tábor

- Omnicut 5000 G – Plasma 3D with bevel cutting torch, possibility of bevel cutting at an angle of max. 45°, format 6000 x 2000 mm

max. cutting thickness of a standard sheet: 80 mm

Plate cutting by scissors

Table scissors

- max width of 3000 mm

- max thickness of 16 mm

Material cutting by carving

- KALTENBACH HDM 1430 saw

- TRENNJAEGER PMC 105 C. saw

- CNC Bomar 540 – automatic saw